Cleaning is the key part of final polishing

Use water and paper towel to clean the glass surface and make sure all dust and fine articles are removed. Set the angle grinder at an average rate, turn it to 1000-1500.

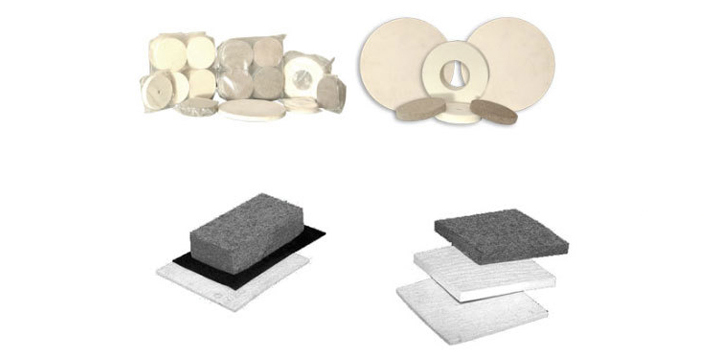

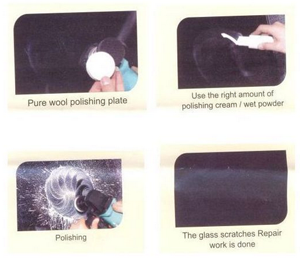

Stick the pure wool plate on the bottom tray, put some polishing cream/polishing powder (wet) on the glass surface. Keep polishing plate parallel against the glass surface. Make it run at an even speed. Use the strength evenly. Spray water consistently and move it regularly.

The polishing zone should be larger than the grinding zone.

During polishing, the glass's temperature will rise rapidly because of the continued friction. Thus it is necessary to check the temperature of the glass and spray water on the glass. Sometimes it's necessary to stop polishing to cool the glass.

The polishing cream will turn into the form of emulsion mud. It's normal. You can keep polishing and spray to cool the glass.

Repeat the above steps. And the polishing cream's concentration will be steadily going low. You can add more for the polishing until the glass become Remove all the residues during polishing. Clean the glass and check it carefully. You will find no scratches on the glass and the glass is as fresh as the new one.

The glass scratches Repair work is done. Polishing cream should be kept away from sunlight and avoid being frozen. Its shape will change when it's frozen but also can be used.

Legal Disclaimer

All products are sold for self-service. We do not guarantee the final result of using the product. We have no any legal responsibility for any disputes arisen from the use of glass, installation of glass and the repair of glass scratches. Our products are safe, with no poisonous side effects. Please keep the products away from children.

Stick the pure wool plate on the bottom tray, put some polishing cream/polishing powder (wet) on the glass surface. Keep polishing plate parallel against the glass surface. Make it run at an even speed. Use the strength evenly. Spray water consistently and move it regularly.

The polishing zone should be larger than the grinding zone.

During polishing, the glass's temperature will rise rapidly because of the continued friction. Thus it is necessary to check the temperature of the glass and spray water on the glass. Sometimes it's necessary to stop polishing to cool the glass.

The polishing cream will turn into the form of emulsion mud. It's normal. You can keep polishing and spray to cool the glass.

Repeat the above steps. And the polishing cream's concentration will be steadily going low. You can add more for the polishing until the glass become Remove all the residues during polishing. Clean the glass and check it carefully. You will find no scratches on the glass and the glass is as fresh as the new one.

The glass scratches Repair work is done. Polishing cream should be kept away from sunlight and avoid being frozen. Its shape will change when it's frozen but also can be used.

Legal Disclaimer

All products are sold for self-service. We do not guarantee the final result of using the product. We have no any legal responsibility for any disputes arisen from the use of glass, installation of glass and the repair of glass scratches. Our products are safe, with no poisonous side effects. Please keep the products away from children.